How to distinguish the advantages and disadvantages of the water-cooled panel of the water-cooled Heat Sink?

Method / step

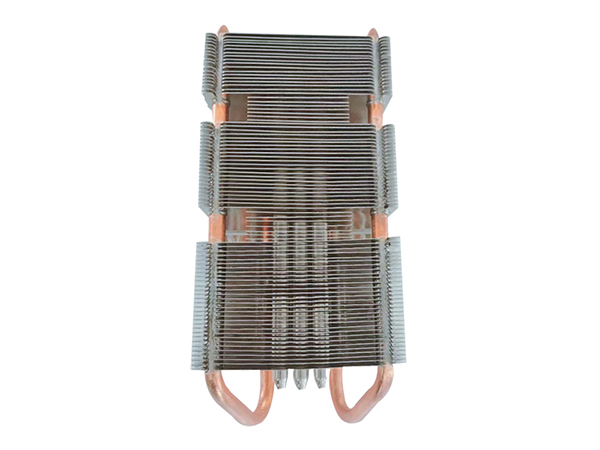

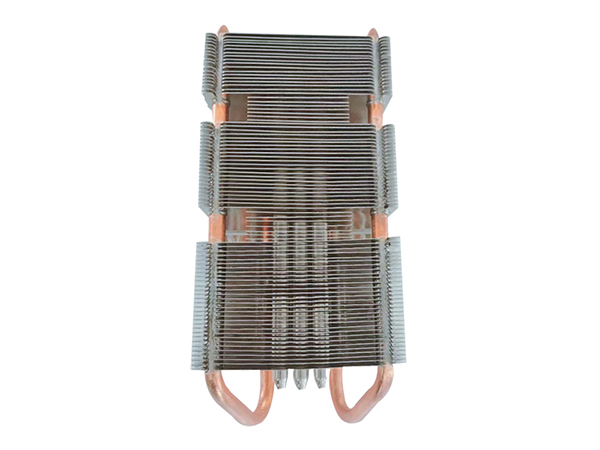

1. Look at the material. Most of the water-cooled heat sinks in the market are designed with copper tubes embedded in aluminum plates. This way of using aluminum and copper alloy for water-cooled plates has high cost performance and relatively low cost. It's hard to see whether there are impurities in the quality of aluminum and copper, that is, the quality of raw materials.

2. Look at the process. The material can be the same, but the process is different, but the effect of Heat Sink is different. We have to start from two aspects to see the process. On the one hand, whether to produce according to the design drawing, and check the parameters indicated in the drawing with vernier caliper. If the error is within 0.05mm, it can be regarded as qualified. If the requirement is high, it can reach 0.02mm precision.

3. On the other hand, from the perspective of the workmanship of water-cooled panels, there will be a problem of adhesion through the process of copper tube embedded aluminum panels. If there is a gap between the two, it will affect the heat dissipation effect and even cause water leakage. The other is that the copper tube and aluminum plate are connected by the process of burying the tube, and then processed by the process of grinding or flying surface, so that the whole water-cooled heat sink plate forms a flat plane, and the quality can also be judged from this plane to see whether it is flat, whether the copper tube and aluminum plate are integrated into a plane, and the gap or unevenness will affect the heat dissipation effect.

4. The advantages and disadvantages of a Heat Sink water-cooled panel can be roughly judged through several aspects. If the requirements are high, you can ask Wenxuan hardware for the actual heat dissipation data, which is more accurate.