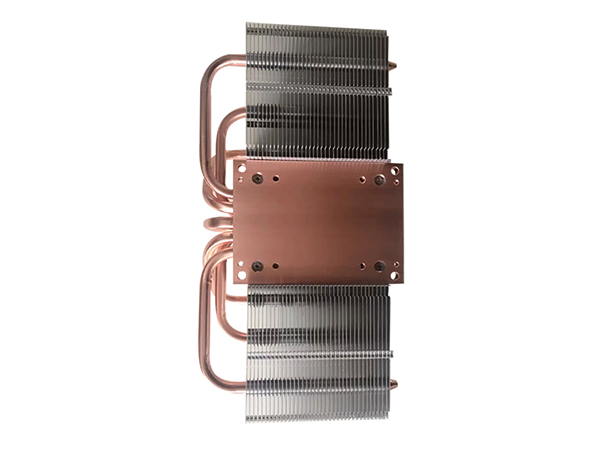

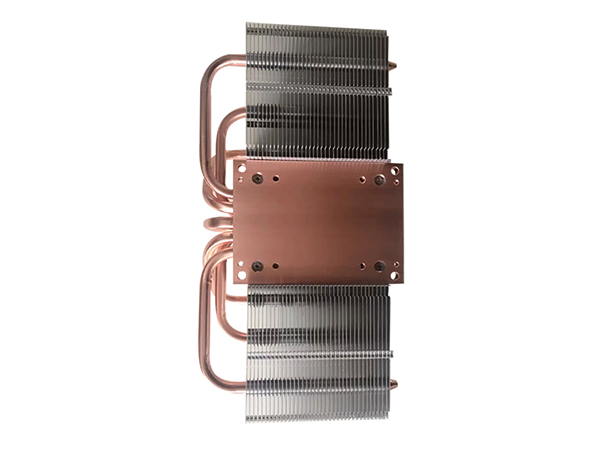

The heat pipe Heat Sink has the advantages of both aluminum Heat Sink and copper Heat Sink. In the case of natural air cooling, the heat resistance * can be as small as 0104e / W, which realizes the heat dissipation under natural conditions. At the same time, a fan with a temperature controller is also set in use, which automatically starts the fan after the ambient temperature is too high, which ensures the long-term rated operation of the power device at a state far below its limit / junction temperature 0. Moreover, the heat pipe Heat Sink has no noise during normal operation, and the equipment has less dust, which brings great convenience to maintenance personnel

(1) Strong heat dissipation. The heat resistance of aluminum (copper) solid Heat Sink is 0103e / W under the wind speed of 6m / s, while that of heat pipe and water-cooling is only 0101e / W under the same conditions

(2) High cost performance. Under the same thermal resistance condition, the heat pipe Heat Sink consumes only half of the aluminum (copper) solid Heat Sink, while the water-cooled Heat Sink not only has more equipment, but also needs to add another water system. At present, there are 3F, 14F and 19F high-power rectifier cabinets in Gezhouba power plant. The principle of loop heat pipe is as follows: loop heat pipe consists of evaporator, steam section, condensation section, return section and compensation chamber. There is a group of capillary structure inside the evaporator, and there are many steam channels on the inner wall or capillary structure of the evaporator. In the actual use process, the temperature rise of power devices in the power cabinet equipped with the loop type heat pipe Heat Sink is low, and they all run far below the limit junction temperature 0, which meets the demand of heat dissipation. However, because of the assembly form of the loop type heat pipe, the whole power cabinet is filled with heat dissipation devices, and the environment temperature in the cabinet is high.

Because of the large size of the loop type heat pipe Heat Sink, the gravity type heat pipe Heat Sink has an impact on the overall heat dissipation in the power cabinet. In 2005, Gezhouba Power Plant tried the gravity type heat pipe Heat Sink on the high-power rectifier cabinet, and achieved good results. At present, it is used in 6 units, such as 2F, 5F, 9F, 10F, 15F, 20f, etc. The principle of gravity type heat pipe is as follows: the gravity type heat pipe is a vacuum sealed tube, which is composed of tube core and working medium liquid. Generally, copper tube is used as shell to resist the pressure difference between the inside and outside of the tube. The working medium can be water or other liquid helium, nitrogen, sodium and potassium. The common one is water. 1. The structure and principle of gravity type heat pipe. Each heat pipe can be It can be divided into three parts: heating (evaporation), heat insulation and condensation. In the heating (evaporation) section, the heat source closely contacts the pipe wall to absorb heat, and the medium liquid (water) evaporates into steam and spreads along the pipe; when it reaches the condensation section with heat sink, the steam condenses into water, releasing the latent heat of vaporization; under the effect of gravity, the water returns to the evaporation section. This completes a heat transfer cycle. As long as the four working cycles of liquid evaporation, steam flow, steam condensation and condensate reflux inside the heat pipe are not damaged, the heat pipe will continuously transfer a large amount of heat from the heat source to the cold end. This does not need external power to achieve, but through the heat transfer margin (steam pressure difference) and medium liquid gravity to drive.